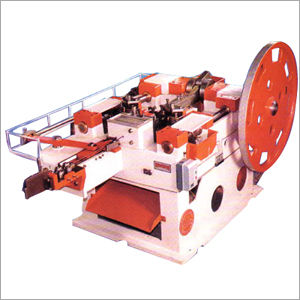

Cup Making Machine

Product Details:

- Product Type Cup Making Machine

- Power Source Electricity

- Power 220-440 Volt (v)

- Surface Treatment Painted

- Color Green

- Click to View more

Cup Making Machine Price And Quantity

- 1 Unit

- 10000.00 - 30000.00 INR/Unit

Cup Making Machine Product Specifications

- Green

- 220-440 Volt (v)

- Cup Making Machine

- Electricity

- Painted

Cup Making Machine Trade Information

- Telegraphic Transfer (T/T) Cash in Advance (CID) Cash Advance (CA)

- 10 Unit Per Month

- 3-15 Days

- All India

Product Description

With an incredulous talent of our competent team of professionals, we are offering our esteemed clients a wide range of Cup Making Machine. This machine is specifically designed with manual feeding system and pneumatic ejection system to make various kinds of cups and cones with high speed. Widely demanded in various food and beverages industry, this machine is known for its high operation and longer working life. Clients can avail this technically advanced Cup Making Machine from us at very affordable price within promised time frame.

Features:

Durable finish standard

Longer working life

Low power consumption

Smooth and noise-free operation

Frequently Asked Questions:

How to start paper cup manufacturing business?

A minimum expenditure of Rs. 10 lakhs is needed to start a paper cut manufacturing facility in order to buy the necessary machinery and raw materials. The paper cups firm can produce over 2.2 million paper cups for an investment of Rs. 10 lakhs, with an expected sales turnover of over 66 lakhs.

How do you manufacture a cup?

Reels are made out of the paperboard for foodservice. The reels are printed and then precisely measured cup sidewall blanks are created from them. The blanks are placed inside cup-forming equipment, which wraps them into the shape of cups and adds the bottom. Heat is applied to the cup seams to make them liquid-proof.

Which material is best for making a cup?

Stainless steel, which is frequently used for travel mugs, is a fantastic insulator. Given that it can accommodate both hot and cold beverages, it is a fantastic material for coffee mugs. Although ceramic is the most popular material, other varieties of mugs also have advantages and disadvantages.

How are eco friendly cups made?

Biodegradable polymers are mostly produced from plant-based materials. PLA is obtained from fermented starch, which is itself obtained from corn, cassava, sugar cane or sugar beet. TPS is produced by heating starch from plant materials with water and mixing with plasticisers.